Filtration during the powder coating process

Powder coating is even more economical now that the clean recovery of overspray is possible. We have been working on this since our company's incepton. We replaced the cellulose with high-quality spunbond polyester in the pleated filter cartridges that are ideal for this purpose. Our customer base is completely satisfied with this innovation, therefore hundreds of thousands of square meters of this material have been put into operation since than.

We make the following filter specifications possible:

operating temperature up to 200°C

IFA M-Class filter

EPA filter classes E11 and E12 according to EN 1822

electrically conductive

galvanized steel designs

stainless steel designs

plastic designs

Products

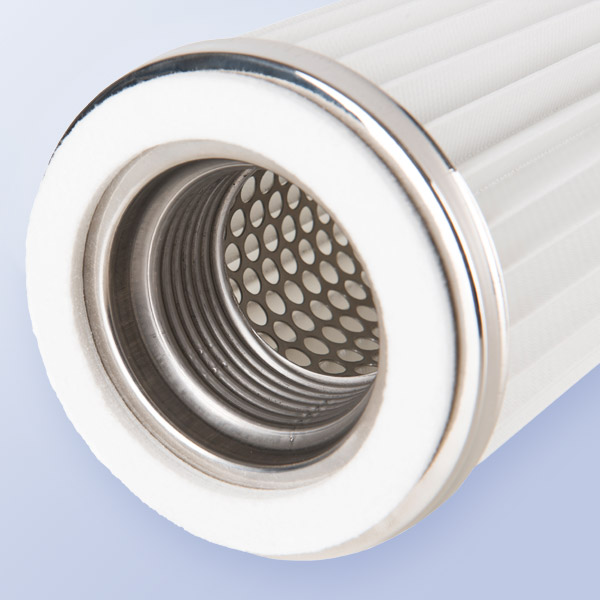

Threaded filter cartridges

Thread sizes

Rd 60 x 4, Rd 72 x 5, Rd 100 x 4

Lengths

up to 2000 mm

Temperatures

up to 200° C

Installation

raw gas side

Applications

versatile use

Features

cylindrical or conical shape

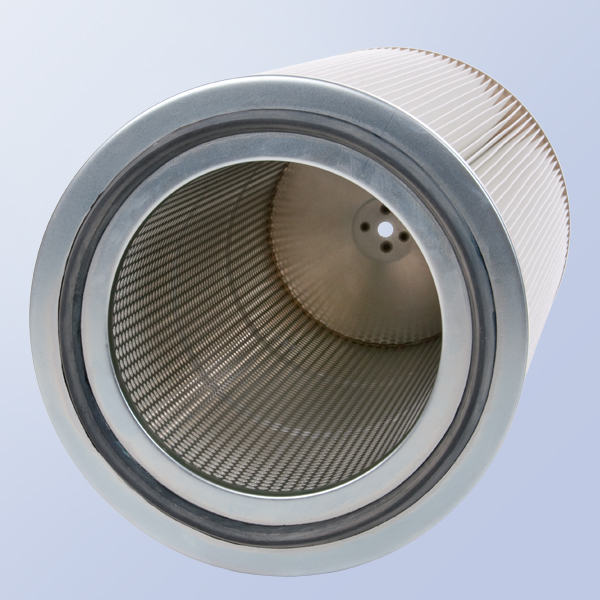

OptiAer

Diameters

120 to 560 mm

Lengths

up to 2000 mm

Temperatures

up to 200° C

Installation

raw gas sides

Applications

versatile use

Features

compact

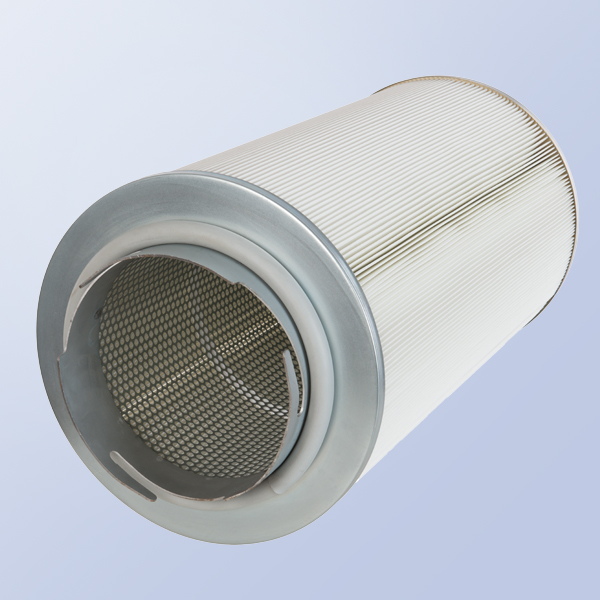

RapidAer

Sizes

145, 156, 218 and 325 mm

Lengths

up to 2000 mm

Temperatures

from -40° C to 200° C

Installation

raw and clean gas sides

Applications

versatile use

Features

- very large filtration area

- open pleat geometry

- high stability

- flanges in polyamide, aluminium, or in various stainless steel finishes, 2/3/4/6 lugs

- 100% incinerable design

Special cartridges

Diameters

custom designs

Lengths

up to 3000 m

Temperatures

up to 200° C

Installation

raw and clean gas sides

Applications

versatile use

Features

- cylindrical or conical shape

- stainless steel types 1.4301, 1.4401, or per customer specification

- individual or series production

- over 30 different filter media

- over 5000 different models