Filtration in the food industry

We supply filtration parts and systems for all areas of the food industry. This includes processing steps that are sensitive and health-related, which must meet the strictest requirements and have independent controls. Our filter cartridges demonstrably comply with the guidelines of Regulations (EC) No 1935/2004 and (EU) No 10/2011. We can also supply electrically conductive filter cartridges upon request. We ground all components to each other for a resistance of under 106 Ohms.

Our products meet your demands:

operating temperature up to 200°C

IFA M-Class filter

EPA filter classes E11 and E12 according to EN 1822

electrically conductive designs

stainless steel designs

plastic designs

Products

NanoAer oval

Sizes

custom designs

Lengths

up to 660 mm or custom

Temperatures

up to 200° C

Installation

raw gas sides

Applications

versatile use

Features

compact

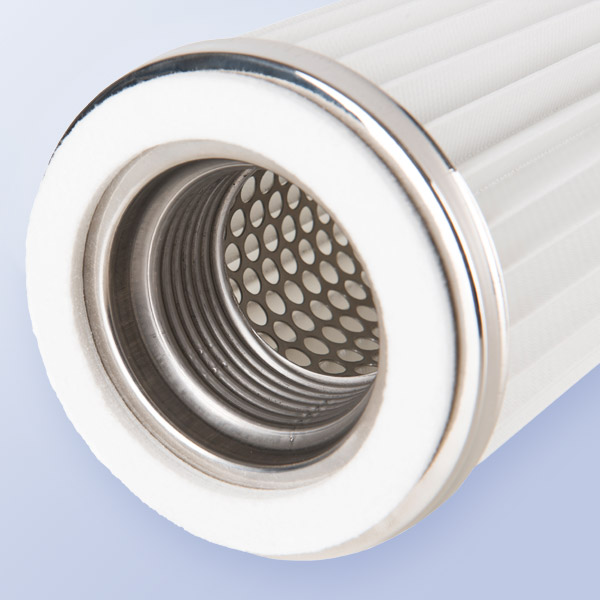

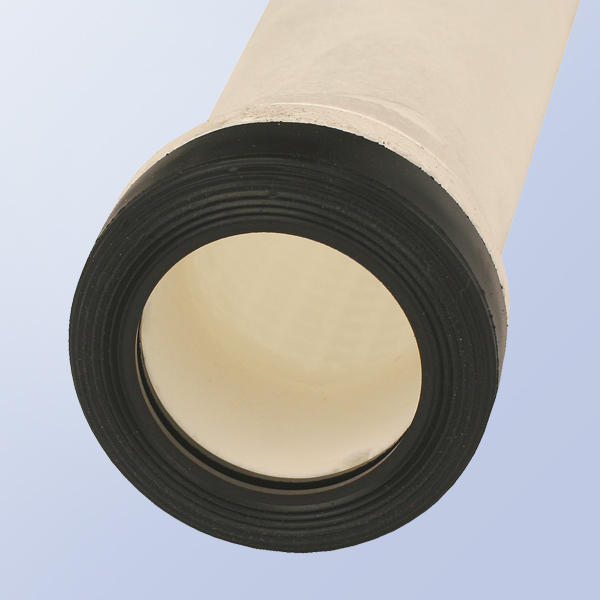

Threaded filter cartridges

Thread sizes

Rd 60 x 4, Rd 72 x 5, Rd 100 x 4

Lengths

up to 2000 mm

Temperatures

up to 200° C

Installation

raw gas side

Applications

versatile use

Features

cylindrical or conical shape

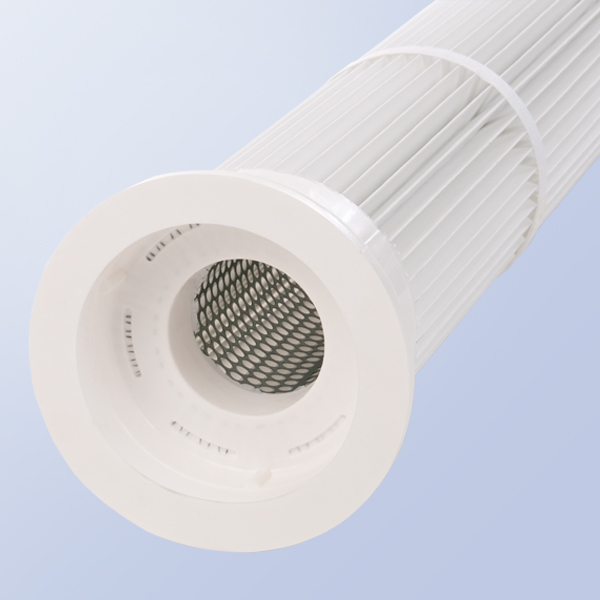

MaxiAer - TopRemoval TR

Sizes

hose replacement cartridge - suitable for head plate opening diameters of 122 to 172 mm

Lengths

up to 3000 mm

Temperatures

up to 200° C

Installation

clean gas sides

Applications

bag replacement cartridge

Features

- one-piece construction

- double to quadruple the filtration area

- up to 30% more air volume

- lower differential pressure

- excellent filtration efficiency

- no modification to cleaning system required

- cleaning pressure up to 4.5 bar

- energy-saving potential

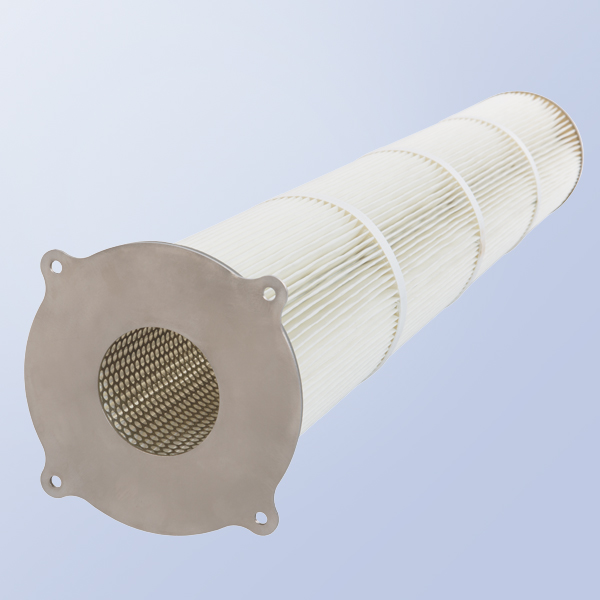

MaxiAer - BottomRemoval BR

Sizes

hose replacement cartridge - suitable for all dust collectors with filter installation on the raw gas side.

Lengths

up to 3000 mm

Temperatures

up to 200° C

Installation

raw gas sides

Applications

bag replacement cartridge

Features

- one-piece construction

- double to quadruple the filtration area

- up to 30% more air volume

- lower differential pressure

- excellent filtration efficiency

- no modification to cleaning system required

- cleaning pressure up to 4.5 bar

- energy-saving potential

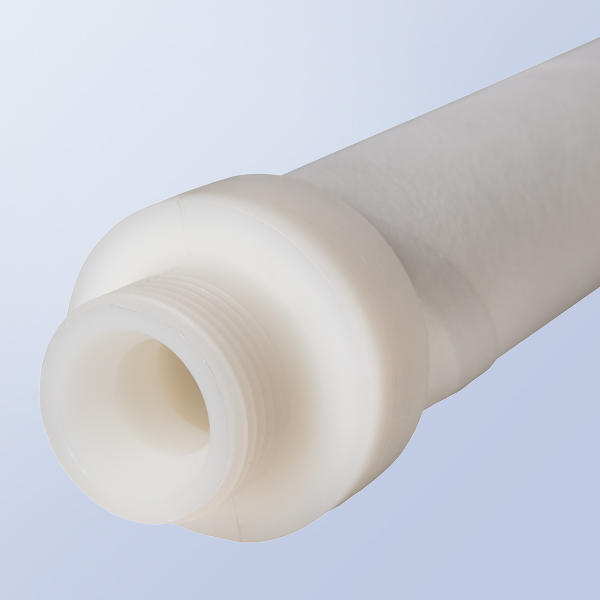

OptiAer

Diameters

120 to 560 mm

Lengths

up to 2000 mm

Temperatures

up to 200° C

Installation

raw gas sides

Applications

versatile use

Features

compact

HELIX Compact filter

Diameters

26, 30 and 45 mm

Lengths

1800 mm

Temperatures

up to 130° C

Installation

raw-/clean gas side

Applications

- for vacuum conveyors and compact filters alternative to SINBRAN filter elements

- alternative to pocket filter (Dalamatic)

- alternative to flat filter

- alternative to Sintamatic and sinter-plate filter

Features

- large filtration area and increased air volume

- high air permeability

- lower differential pressure

- excellent filtration efficiency

- first-class cleaning characteristics

- suitable for pulse-jet cleaning

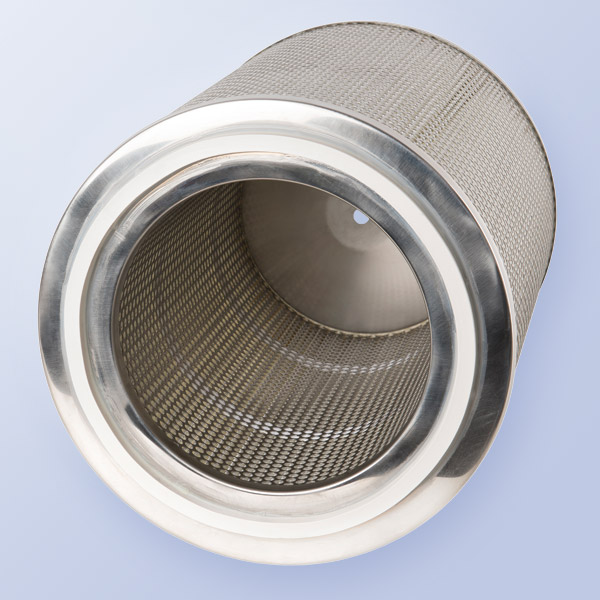

Special cartridges

Diameters

custom designs

Lengths

up to 3000 m

Temperatures

up to 200° C

Installation

raw and clean gas sides

Applications

versatile use

Features

- cylindrical or conical shape

- stainless steel types 1.4301, 1.4401, or per customer specification

- individual or series production

- over 30 different filter media

- over 5000 different models